- +91 - 9880470436

- info.anagha@gmail.com

Wet Collector

Anagha Wet Dust Collector

Anagha Systems mainly manufacture Four types of Wet Scrubbers. These scrubbers are generally used for different kind of application where fabric filters some time fail to arrest pollutant. Following are the main four types of Wet Scrubbers Manufactured by Anagha

- Ventury Scrubber

- Packed Bed Scrubber

- Low Energy scrubber

Technical Details:

All the Models manufactured are Tailor Made On the basis of actual data gathered by Anagha Representative. Detail available on request.

Application:

- Metal Forming - Oil and Smoke

- Material Processing - Particulate/Fume

- Textiles & Tenterframe

- Exhaust (Lint/Oil)

- Coatings - Spray Booth VOC

- Restaurants - Grease and Smoke

- Humidifier Evaporator

- Air Washer

- Process Liquid and Gas Cooler

- Efficient

- Low maintenance

- Low water usage

- Proven

Ventury Type Scrubber (Vertical & Horizontal):

The design of the Anagha Venturi Scrubber consists of a ?wet approach? venturi followed by a liquid entrainment separator. Dust laden gases enter the venturi and instantly make contact with the tangentially introduced scrubbing liquid swirling down the venturi?s converging walls. At the venturi throat, the gas and liquid streams collide and the liquid breaks down into droplets which trap dust particles.

This gas/liquid mixture passes through a flooded elbow, and then enters the entrainment separator through a tangential inlet. Centrifugal action removes the heavy wetted particles from the gas stream. As an alternate, when very large diameter separators are required, the liquid is separated by passing the stream through a chevron-type mist eliminator baffle. The dust/liquid mixture is discharged from the separator bottom drain and the cleaned gas leaves through the top of the separator.

Packed Bed Scrubber (Vertical & Horizontal):

The Anagha Vertical Packed Bed Scrubber is custom designed for each application to provide high efficiency, low cost gas cleaning. The packing media is uniquely shaped to provide abundant surface area to provide intimate contact between the gas and scrubbing liquid. The resultant effect is high scrubbing efficiency, allowing optimum packing section length with a compact design and low pressure drop. Several configurations and options are offered for the Anagha Vertical Packed Bed Air/Gas Scrubber. Multiple units, vertical and horizontal models, special materials, and integration into complete environmental control systems are all available.

Ideally suited for

- Acid fumes

- Chemical fumes

- Chemical odors

- Food processing odors

- Metal finishing fumes

- Steel processing fumes

- Sulphur based fumes

Low Energy Scrubber(Vertical & Horizontal):

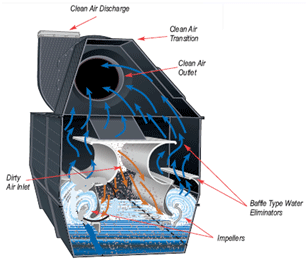

Anagha Low Energy Scrubber cleans the air by the combined action of centrifugal force and a thorough intermixing of water and dustladen air. The dust is separated from the air by a water curtain, created by the flow of air through a partially submerged stationary impeller. Air flowing through the impeller at a high velocity conveys a turbulent sheet of water with it.

The centrifugal force exerted by rapid changes in direction of flow causes the dust particles to penetrate the water film and become permanently trapped. Entrained water droplets in the cleaned air are removed by specially designed, wide-space chevron eliminators for smaller collectors or three curved de entrainment baffles for larger collectors. The water in the reservoir is continually used. Since the water curtain is produced by the airflow, no pumps or nozzles are required.

Application

- Explosive Dust

- Material Handling

- Rubber Grinding Metalworking

- Chemicals

- Mining

Cross Flow Scrubber (Vertical & Horizontal):

Anagha?s Cross-Flow scrubber is an effective suppression system which is able to solve the filtration problems that with other solutions would be difficultly faceable. In particular it finds its best application in the suppression of dusts that are dangerous due to their explosivity or inflammability, or in presence of effluents that tend to impact on the traditional cartridge or bag filters. The machine is made up of a parallelepiped with inclined bottom, supported by four steady feet of various lengths. The face is closed by a transparent material slab, secured by screws, that allows the internal visual inspection.

Venturi scrubbers achieve very high collection efficiencies for respirable dust. Since efficiency of a venturi scrubber depends on pressure drop, some manufacturers supply a variable-throat venturi to maintain pressure drop with varying gas flows.